Temperature Gauges

Bimetal Dial Thermometer

The Bimetal thermometer employs a bimetal strip in the form of helix, it works on the principle of thermal expansion - two metals having different coefficient of expansions are joined together to form a bimetal. The resultant expansion of bimetal is proportional to temperature that is sensed. Bimetal dial thermometers are simple in construction, but rugged.

They are used for measurement of temperature in most of the industrial applications. They are offered in the range of (-) 50°C to 500°C. With rigid stem having bottom or back entry. It can also be offered in every angle rotatable construction at 180° A

Features

Protection class IP-67

Accuracy ± 1% FSD

Fast response

Bottom/Back entry, every angle construction

High repeatability, low hysteresis

Hermetically sealed case

| Specifications | |

|---|---|

| Reference standard: | ASME B 40.3, EN 13190 |

| Dial | 63mm,100mm,125mm,150mm in aluminium white background, black markings |

| Case | Die cast aluminium with screwed bezel SS304/SS316 with bayonet bezel |

| Protection | Weatherproof to IP - 67 (IS/IEC 60529:2001) Window : Shatterproof / Toughened glass / Acrylic for Switches |

| Pointer | Aluminium, black |

| Stem | SS304 or SS316 in 6mm,8 mm,10mm,12mm, 14mm,1/4”, 3/8”,1/2”, 5/8” dia and length from 100mm to 1200 mm as standard |

| Connection | ½" NPT (M) as standard in SS304 or SS316 adjustable three piece compression fitting (Any other on request) |

| Range | (-) 50°C to 500°C with a minimum span of 80°C (0-600°C-optional) |

| Accuracy | ±1% FSD (±2% FSD for 63mm dial size) (In accordance with EN 13190) |

| Over range | 125% FSD (110% for 500°C) |

| Reset | External |

| Contact | Single SPST, normally open, closed on rise in temperature (specify action required) adjustable over the entire range, rating 30 VA @ 230 V AC (100mm dial back entry model in SS case only ) |

| Optional | The following can be provided on request 1) Silicon filled for Dampening the Vibrations (Maximum Range:0 to 400°C on account of Limitation of Silicon due to Temperature) 2) Color Band Dials 3) Dual Scale Dials 4)130% Over range 5) Pointer Stopper for Over range and Under range 6) Range of 0 to 600°C 7) Accuracy (±0.5% FSD) 8) Spring loaded Glands and Nipple Union Nipple assemblies measurements (Skin Type) can be provided on request |

Mercury in Steel Dial Thermometer

Mercury filled system based on mercury expansion principle is used for measuring temperature ranging from (-) 40°C to 650°C. It has faster response and the same is available in rigid stem as well as capillary type for remote sensing. Every angle type can be offered in all SS construction. Manufactured in accordance with BS:5235.

System is case compensated as standard (SAMA Cl VB). Fully compensated (capillary compensation), Double Bourdon system is also offered wherever essential.

Features

Rugged construction

Rigid stem or capillary type

Fast response

Protection class IP- 67

Accuracy ± 1% FSD

High repeatability, low hysteresis

Case compensated system

Micrometer Pointer for Reset

| Specifications | |

|---|---|

| Reference standard: | BS 5235, EN 13190 |

| System | Mercury filled, case compensated in accordance with SAMA CI. V B |

| Dial | 63mm,100mm,125mm,150mm in aluminium white background, black markings |

| Case | Die cast aluminum with screwed bezel in SS304 / SS316 with bayonet bezel as standard |

| Protection | Weather proof to IP - 67 (IS/IEC 60529:2001) |

| Window | Shatterproof / Toughened glass / Acrylic |

| Pointer | Aluminium, black |

| Stem | SS304 or SS316 in 6mm, 8mm,10mm,12mm, 14mm,1/4”, 3/8”,1/2”, 5/8” dia (immersion length as small as 30mm possible) |

| Capillary | SS Solid drawn |

| Capillary Covering | SS covered / SS covered + PVC / SS armoured / SS covered+SS armoured+PVC / (upto 5 Mtrs) |

| Connection | ½" NPT (M) as standard in SS304 or SS316 adjustable three piece compression fitting (Any other on request) |

| Range | (-) 30°C to 250°C with a minimum span of 50°C (0-600°C-optional) |

| Accuracy | ±1% FSD |

| Over range | 125% FSD as standard |

| Zero reset | Micrometer Pointer |

| Optional | The following can be provided on request 1) Silicon filled for SS304 / SS316 case (Maximum Range: 0 to 400°C on account of Silicon Limitation of Temperature) 2) Pointer Stopper for Over range and Under range 2) Color Band Dials 3) Dual Scale Dials 4) 130% Over range 5) Spring loaded Glands and Nipple Union Nipple ssemblies (Skin Type) can be provided on requests |

Liquid Filled Dial Thermometer

Liquid filled system based on liquid (other than mercury) expansion principle is used for measuring temperature ranging from (-) 30°C to 250°C.

It has faster response and the same is available in rigid stem as well as capillary type for remote sensing. Every angle type can be offered in all SS construction. Generally used where mercury type thermometer is not used in industries such as Food, Pharmaceutical, etc. The main advantage is its minimum immersion length required for sensing (as low as 30mm suffices for proper sensing thereby making it ideal for installing in lower line sizes)

Features

Rugged construction

Rigid stem or capillary type

Suitable for pharmaceutical, food, biotechnology industry.

Protection class IP-67

Accuracy ± 1% FSD

Minimum immersion length (as low as 30mm suitable for lower line sizes) possible.

Case compensated system (SAMA Cl. IB)

| Specifications | |

|---|---|

| System | Liquid filled, case compensated in accordance with SAMA CI. I B |

| Dial | 100mm or 150mm in aluminium, white background, black markings |

| Case | Die cast aluminum with screwed bezel, SS304 / SS316 with bayonet bezel |

| Protection | Weatherproof to IP - 67 (IS/IEC 60529:2001) Window : Shatterproof / Toughened glass / Acrylic for Switches |

| Pointer | Aluminium, black |

| Stem | SS304 or SS316 in 6mm,8 mm,10mm,12mm, 14mm,1/4”, 3/8”,1/2”, 5/8” dia and length from 100mm to 1200 mm as standard |

| Connection | ½" NPT (M) as standard in SS304 or SS316 adjustable three piece compression fitting (Any other on request) |

| Range | (-) 50°C to 500°C with a minimum span of 80°C (0-600°C-optional) |

| Accuracy | ±1% FSD (±2% FSD for 63mm dial size) (In accordance with EN 13190) |

| Over range | 125% FSD (110% for 500°C) |

| Reset | External |

| Contact | Single SPST, normally open, closed on rise in temperature (specify action required) adjustable over the entire range, rating 30 VA @ 230 V AC (100mm dial back entry model in SS case only ) |

| Optional | The following can be provided on request 1) Silicon filled for Dampening the Vibrations (Maximum Range:0 to 400°C on account of Limitation of Silicon due to Temperature) 2) Color Band Dials 3) Dual Scale Dials 4)130% Over range 5) Pointer Stopper for Over range and Under range 6) Range of 0 to 600°C 7) Accuracy (±0.5% FSD) 8) Spring loaded Glands and Nipple Union Nipple assemblies measurements (Skin Type) can be provided on request |

Gas Filled Dial Thermometer

Gas filled temperature gauge overcomes most of the limitations of other members of family. It is offered in a very wide temperature range i.e. (-)200 to 800°C.

Practically any stem length can be offered and capillary length as long as 25 Mtrs without any loss of accuracy. Inert, non hazardous, non toxic nature of the gas filled system makes it virtually ideal choice of cross section of industries.

Features

Use of inert gas – N2

Suitable for sanitary application

All SS construction

Rigid stem or capillary type

Fast response

Non-polluting, environment friendly

Non-hazardous for the service

High reliability

IP-67 protection

Accuracy ± 1% FSD

| Specifications | |

|---|---|

| System | Gas (N2) filled, case compensated in accordance with SAMA Cl. III B |

| Dial | 63mm,100mm,125mm,150mm, 250mm in aluminium, white background, Black markings |

| Case | SS304 / SS316 with bayonet bezel |

| Protection | Weatherproof to IP-67(IS/IEC 60529:2001) |

| Window | Shatterproof / Toughened glass / Acrylic for Switches |

| Pointer | Aluminium, black with micrometer adjustment |

| Stem | SS316 in 8mm,10mm,12mm,1/4”,3/8”,1/2”, 5/8” dia as standard, SS310 for ranges above 600°C |

| Capillary | SS Solid drawn |

| Capillary Covering | SS covered / SS covered + PVC / SS armoured armoured + PVC / SS + SS armoured (up to 25 Mtrs). |

| Connection | 1/2"NPT (M) adjustable three piece compression fitting in SS304 or S316. (Any other on request) |

| Range | (-) 200°C to 800°C with minimum span of 80°C |

| Accuracy | ± 1% FSD in accordance with EN 13190 |

| Over range | 125% FSD upto 600°C, 110% for 800°C |

| Zero Reset | Micrometer pointer |

| Optional | The following can be provided on request 1) Silicon filled case (Maximum Range : 0 to 400°C on account of Silicon Limitation of Temperature) 2) Pointer Stopper for Over range and Under range 3) Color Band Dials 4) Dual Scale Dials 5) 130% Over range 6) Accuracy (±0.5% FSD) for Rigid Stem or Capillary Models maximum Length upto 3 Mtrs 7) Any Non Standard Bulb Design on request 8) Spring loaded Glands and Nipple Union Nipple assemblies 9) Surface Temperature measurements (Skin Type) can be provided on request. |

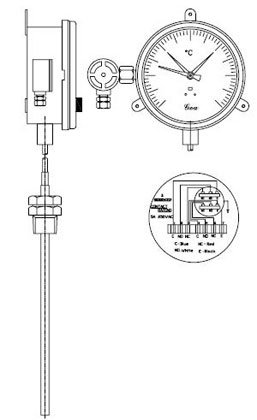

Indicating Temperature Switch

Indicating temperature switch combines indication with switching (in order to make or break the associated electrical circuit). Can be offered with contact assembly as well as microswitch assembly (as a combination of switch and movement)

Features

Combination of indication and switching

Fast response

Choice of contact assembly or microswitch

Switching accuracy ± 2%FSD

High repeatability and low hysteresis

Case compensated system

| Specifications | |

|---|---|

| System | Mercury filled or Gas (N2) filled case compensated in accordance with SAMA C1. V B/IIIB |

| Dial | 100mm or 150mm, white anodised, black markings |

| Case | SS304 / SS316 with bayonet bezel or Aluminium Case/Bezel (See note) |

| Protection | Weatherproof to IP - 67 (IS/IEC 60529:2001) |

| Window | Acrylic |

| Pointer | Aluminium, black |

| Stem | SS304 or SS316, 6mm, 8mm,10mm,12mm |

| Connection | 1/2" NPT (M) adjustable three piece compression fitting as standard |

| Capillary | 1/2" NPT (M) adjustable three piece compression fitting as standard |

| Capillary Covering | SS Solid drawn SS covered or SS armoured or SS covered with PVC up to 10 Mtrs for Mercury Filled and 25 Mtrs for Gas Filled. |

| Range | (-) 40°C to 600°C with a minimum span 50°C for mercury filled temperature switch / (-)200 to 600°C or upto 0-800°C for gas filled temperature switch (minimum span 80°C) |

| Accuracy | ± 1% FSD for indication, ± 2% FSD for switching |

| Over range | 125% FSD as standard (130% FSD on request upto 500°C) |

| Contacts | 1) 1 SPST, single, normally open, closed on rise in temperature or vice versa, rated 30 VA @230V AC 2) 2 SPST, two contacts, independently adjustable, one normally open other normally closed or both normally open or both normally closed, rated 30VA @ 230 V AC 3) 1 SPDT, single microswitch, adjustable over entire range, rated 5 amp @ 230 V AC (3A @ 28 VDC) 4) 2 SPDT, double microswitch, adjustable over entire range, rated 5 amp @ 230 V AC (3A @ 28 VDC) |

| Accessory | Relay for the contact assembly to suit 5 amp @ 230 V AC, separately mounted. |

| Note | 1) 2 SPDT only in 150mm dial size. 2) SPDT contacts in SS case only 3) SPST contacts in Aluminium Case only 4) For minimum immersion length essential for proper sensing, contact our design department. |

| Advantages of Microswitch Type Models | 1) Microswitch is rated 5 amp @ 230 V AC (3A @ 28 VDC). No relay is required. 2) Microswitch assembly is imported, having combination of movement and switch. 3) Microswitch assembly gives better switching accuracy. Compact design. |

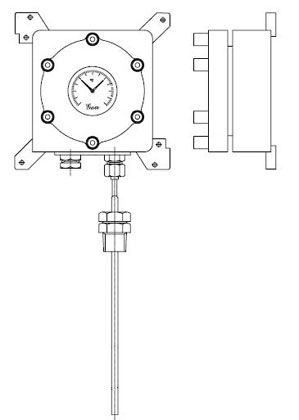

Flameproof Indicating Temperature Switch

Flameproof Indicating temperature switch combines indication with switching (in order to make or break the associated electrical circuit). Can be offered with microswitch assembly (as a combination of switch and movement)

Features

Combination of indication and switching

Fast response

Switching accuracy ± 2% FSD

High repeatability and low hysteresis

Flameproof housing

Case compensated system

| Specifications | |

|---|---|

| System | Mercury filled or Gas (N2) filled case compensated in accordance with SAMA C1. V B/IIIB |

| Dial | 100mm (Internal), white anodised, black markings |

| Housing | Flameproof to IIA IIB (Equivalent to NEC C1. I Div 2 Gr. C & D) |

| Housing Material | Aluminium LM 6 |

| Dimensions | 230mm x 255mm |

| Window | Toughened Glass |

| Stem | SS304 or SS316, 6mm, 8mm,10mm,12mm |

| Connection | 1/2" NPT (M) adjustable three piece compression fitting as standard |

| Capillary | SS Solid drawn |

| Capillary Covering | SS covered or SS armoured or SS covered with PVC up to 10 Mtrs. For Mercury filled and 25 Mtrs for Gas filled. |

| Range | ((-) 40°C to 600°C with a minimum span 50°C for mercury filled temperature switch / (-) 200 to 600°C for gas filled temperature switch (minimum span 80°C) |

| Accuracy | ± 1% FSD for indication, ± 2% FSD for switching |

| Over range | 125% FSD as standard (130% FSD on request upto 500°C) |

| Contacts | 1) 1SPDT, single microswitch, adjustable over entire range, rated 5 amp @ 230 V AC (3A @ 28 VDC) 2) 2 SPDT, double microswitch, adjustable over entire range, rated 5 amp @ 230 V AC (3A @ 28 VDC) |

| Note | 1) Surface mounted flameproof housing is available with capillary. 2) Flameproof (conforming to IIC) version also available with microswitch. 3) For minimum immersion length essential for proper sensing, contact our design department |

| Advantages of Microswitch Type Models | 1) Microswitch is rated 5 amp @ 230 V AC (3A @ 28 VDC). No relay is required 2) Microswitch is imported from reputed international supplier as combination of movement and switch. 3) Microswitch assembly gives better switching accuracy. Compact design. |

Different Types of Temperature Gauges

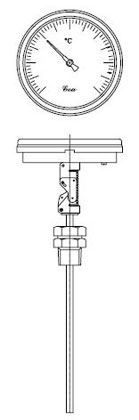

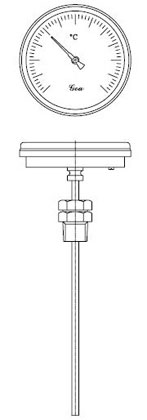

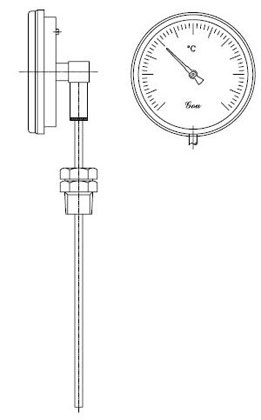

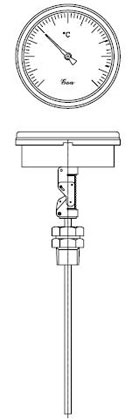

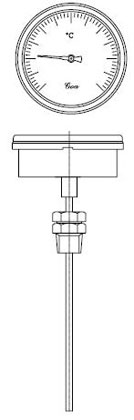

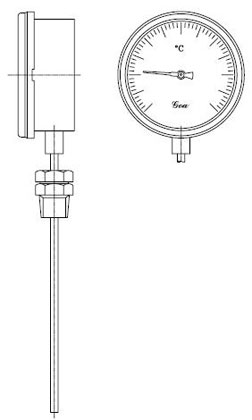

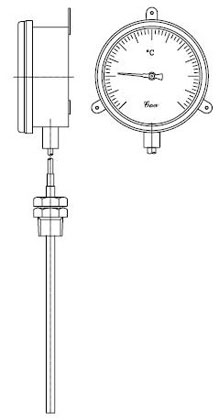

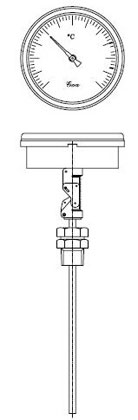

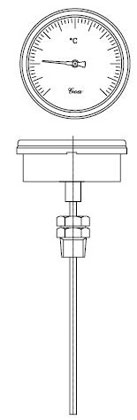

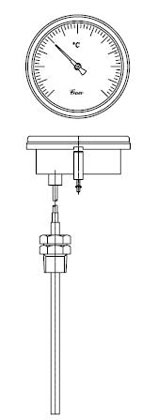

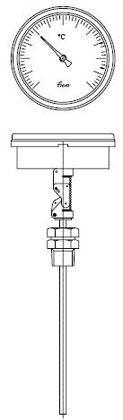

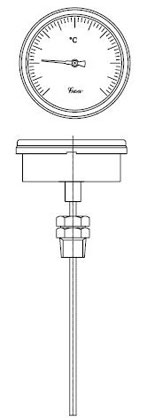

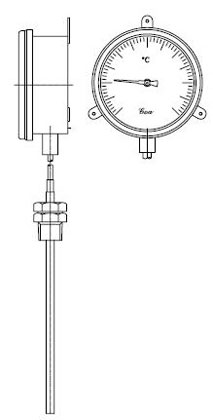

Bimetal Type

Figure 1. (Every angle)

Figure 2. (Back entry)

Figure 3. (Bottom entry)

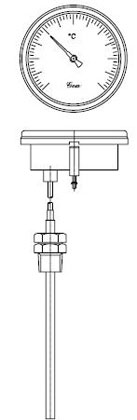

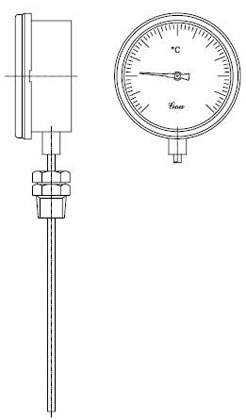

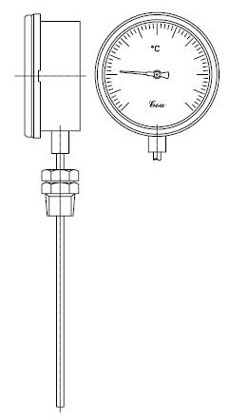

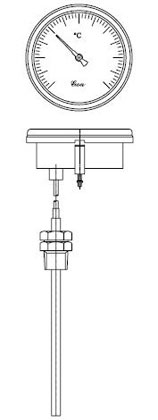

Gas Filled Type

Figure 1. (Every angle)

Figure 2. (Back entry)

Figure 3. (Bottom entry)

Figure 4. (Bottom entry, capillary)

Figure 5. (Back entry, capillary)

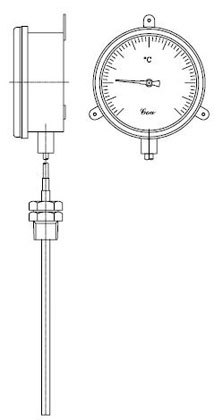

Mercury Filled Type

Figure 1. (Every angle)

Figure 2. (Back entry)

Figure 3. (Bottom entry)

Figure 4. (Bottom entry, capillary)

Figure 5. (Back entry, capillary)

Liquid Filled Type

Figure 1. (Every angle)

Figure 2. (Back entry)

Figure 3. (Bottom entry)

Figure 4. (Bottom entry, capillary)

Figure 5. (Back entry, capillary)

Indicating Temperature Switch

Figure 1. (Temperature switch)

Figure 2. (Flameproof enclosure)

In-House Testing facilities for Temperature Gauges

For the manufacturing & testing of temperature gauges, we strictly follow EN : 13190-2001 and DIN 16203, 16204, 16205 and 16206 standard.

Following tests are carried out to ensure the quality of temperature gauges. We have facilities to carry out following tests in-house at our manufacturing plant.

- Accuracy Test

- Over range Test

- End Nipple Test(For Bimetal Temperature Gauges)

- Hysteresis Test

- Hose Down Test (Water Spray Test)

- Response Time Test

- Switching Accuracy Test (For Contact Assembly & Microswitch Type Models)

- Repeatability Test

- Vibration Test (Rattling Test)

- Load Test

- Mounting Position Test

- Ambient Temperature Compensation Test (Case Compensation Test)

- Capillary Compensation Test

- Hermetical Sealing Test (For Bimetal Temperature Gauges)

- Thermal Stability Test

- High Voltage Test (For Contact Assembly & Microswitch Type Models)

- Insulation Test

- Contact Resistance Test

- Altitude Test

- Dial Printing Stability Test

- Cyclic Test

- Friction Test

- Helium Leak Test

- Life Test for SPDT movement

.jpg)